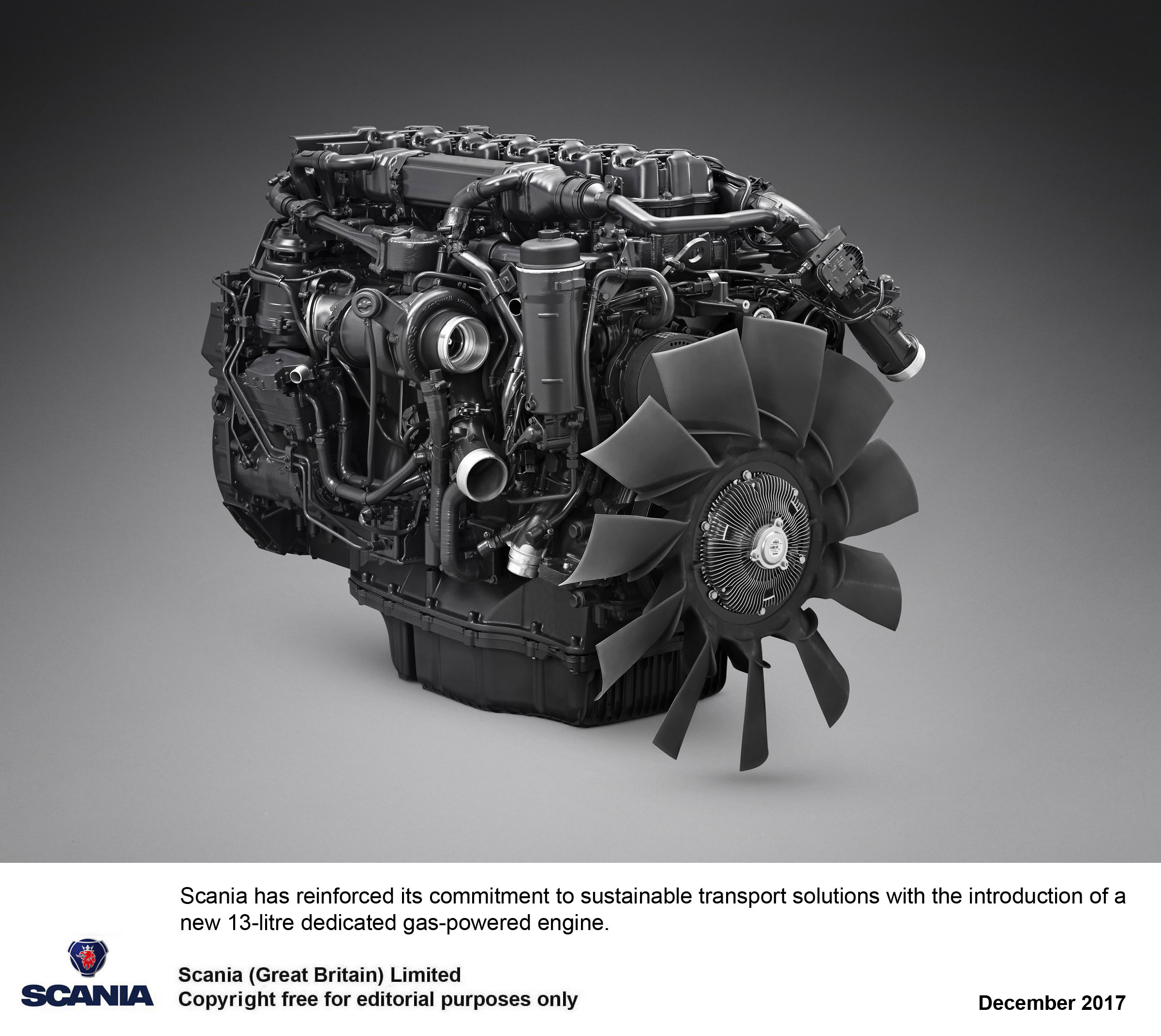

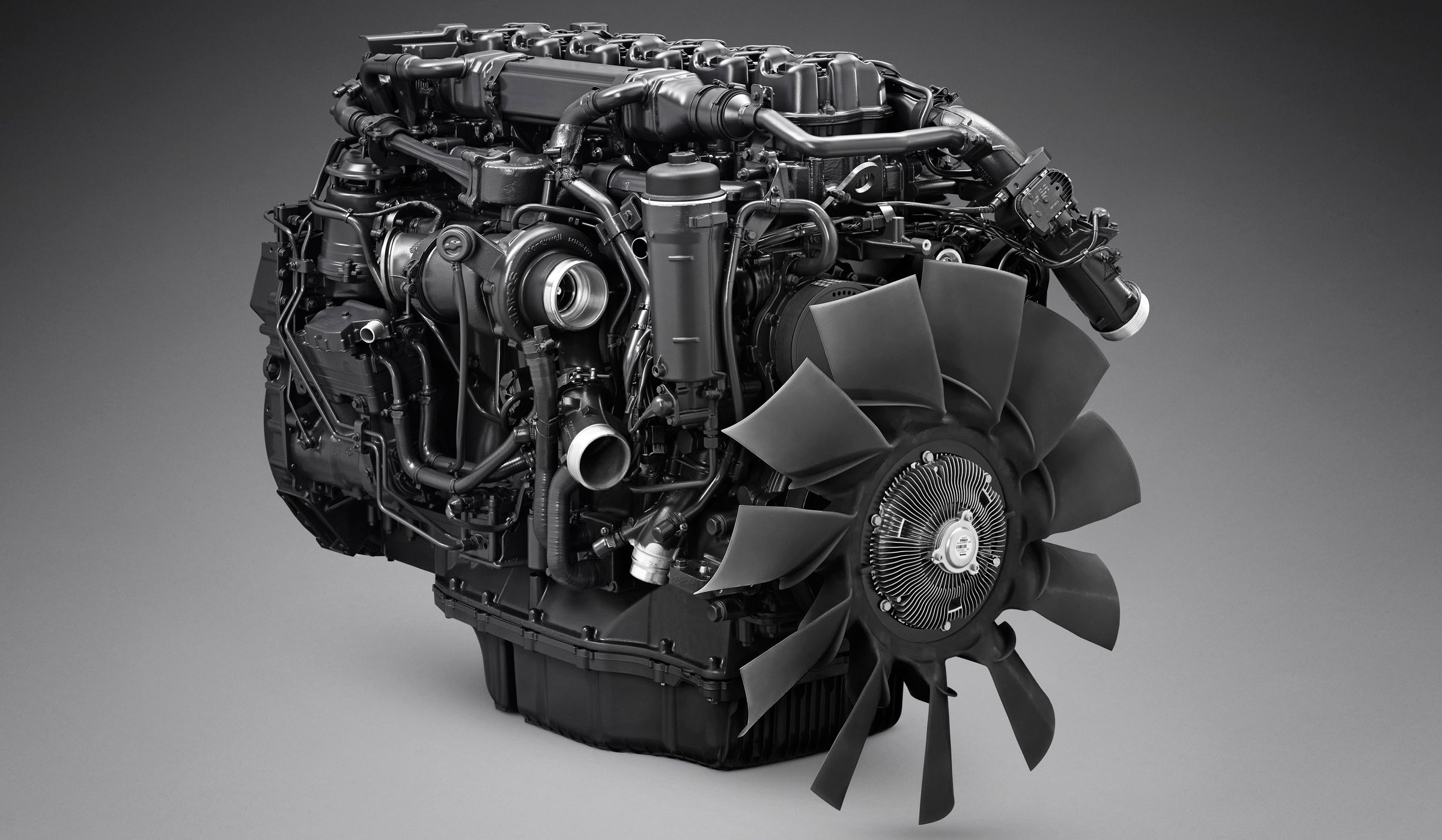

Scania has reinforced its commitment to sustainable transport solutions with the introduction of a new 13-litre dedicated gas-powered engine. Rated at 410 horsepower, the new engine joins Scania’s existing 280 and 340 horsepower nine-litre dedicated gas units.

“With 2,000 Nm torque from 1,100rpm through to 1,400rpm, the new 13-litre gas engine delivers similar performance to comparable diesel engines,” says Andrew Jamieson, Sales Director for Scania (Great Britain) Limited. “Furthermore, when running on biogas, emissions of carbon dioxide are reduced by up to 90 percent. As such, this new engine will appeal to operators looking to switch to a renewable and sustainable fuel source while reducing their environmental impact without compromising performance.”

The new 13-litre engine can be specified on a range of Scania G- and R-series trucks, including 4×2 tractor units and 4×2, 6×2, 6×2*4 and 8×4*4 rigids, with vehicles operating on Compressed Natural Gas (CNG), Compressed Bio Gas (CBG) or Liquefied Natural Gas (LNG). In CNG/CBG format, a total of eight gas tanks are fitted. These are either 95 or 118-litres each, depending on wheelbase and battery position, giving a maximum capacity of 944-litres. This equates to a range of up to 500 kilometres, depending on road conditions and the type of application. For LNG tractor units, two tanks provide a capacity of 740-litres and a range of up to 1,000 kilometres, while LNG rigids can accommodate single or double tanks, giving a capacity of 400-1,100-litres and a maximum range of up to 1,600 kilometres.

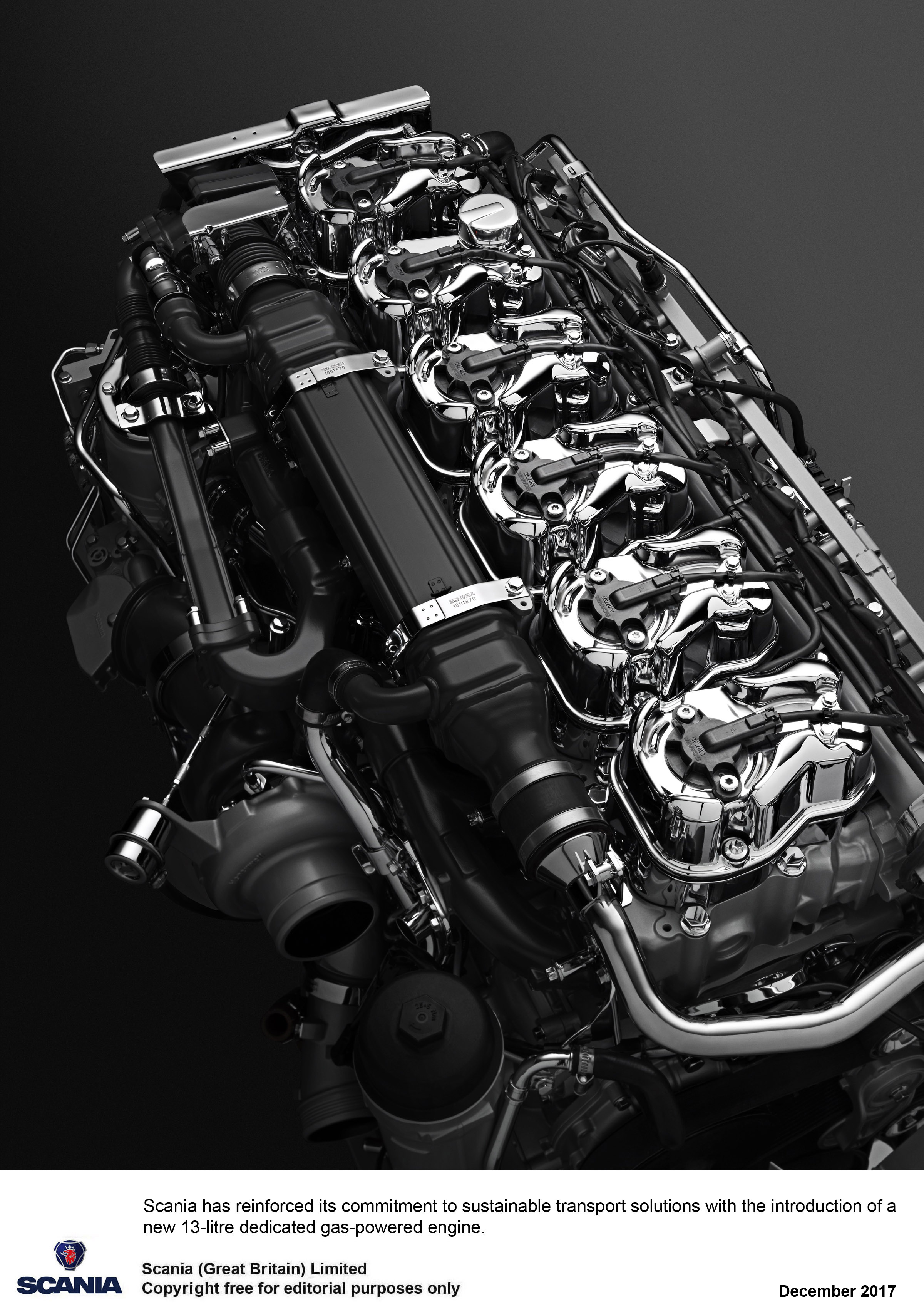

Designated OC13 101 and based on Scania’s proven six-cylinder 13-litre engine platform, the new dedicated gas-powered unit is the outcome of a comprehensive development programme which utilises the Otto principle and stoichiometric combustion, where all fuel and oxygen is burnt completely. Combustion is initiated using spark plugs, and pre-mixing takes place prior to the fuel entering the cylinders.

With driveability a key factor for Scania’s engineers, the new 13-litre engine has been designed to always operate with Scania Opticruise, Scania’s fully-automated gear-selection system, ensuring fast and smooth gear-changing and high levels of driver comfort.

Extended maintenance intervals

Gas engines which operate on the Otto principle (with pre-mixing of fuel and with spark plugs) have shorter service intervals than diesel engines. However, Scania’s engineers have implemented a series of measures that help bring about a significantly longer service intervals. Today it is the service life of the spark plugs that typically sets the limits.

“We have set the interval at 45,000 kilometres for both spark plug replacement and oil changes under normal use,” says Senior Engineer Folke Fritzson, a member of Scania’s gas engine research and development team. “This is a clear improvement over previous generations of gas engines, which had a normal service interval of 30,000 kilometres, and therefore reduces maintenance costs and increases uptime.”

The Scania dedicated gas engine programme

| OC09 104

280 hp |

OC09 105

340 hp |

OC13 101

410 hp |

|

| Type | Inline | ||

| Displacement | 9.3 litres | 12.7 litres | |

| Firing order | 1-2-4-5-3 | 1-5-3-6-2-4 | |

| Cylinders | 5 | 6 | |

| Valves per cylinder | 4 | ||

| Bore x stroke | 130 x 140 mm | 130 x 160 mm | |

| Cam type | Normal | ||

| Compression | 12.6:1 | 12.6:1 | |

| Fuel injection | Bosch | ||

| Emission control | Scania EGR and 3-way catalytic converter | ||

| Oil capacity | 31 litres | 43 litres | |

| Max. output | 280 hp (206 kW)

at 1900 rpm |

340 hp (250 kW)

at 1900 rpm |

410 hp (302 kW)

at 1900 rpm |

| Max. torque | 1350 Nm at

1100-1400 rpm |

1600 Nm at

1100-1400 rpm |

2000 Nm at

1100-1400 rpm |

For more information please visit keltruckscania.com/products.